Workers’ safety shoes have come a long way, and there are more options available these days than ever before. It’s good news for workers who face risky environments that their safety and protection have been taken into consideration when designing and manufacturing these shoes. Let’s take a look at how industrial shoe technology has evolved throughout the years and the best approach for proper footwear selection that offers injury protection.

How Does Industrial Shoe Technology Enhance Worker Protection?

Safety is a good foundation for productive workers. Therefore, it is important to invest in the right pair of safety and industrial shoes that ensure the well-being of employees so they can perform their best. The following features and innovation show how far the industry has come in keeping workers out of harm’s way.

1. Customize Shoes & Features to Jobsite

Workplace hazards are divided into several categories. Depending on which industry you are a part of, you could fall under one or more of these workplace hazards:

- Safety Hazard – It refers to risks present due to falling objects or heavy objects that can accidentally drop on their feet, or objects falling from above. It is highly common on construction sites. In fact, falls and slips rank among the biggest hazards on a construction site.

- Physical Hazard – It refers to the exposure to potentially harmful substances, especially when exposed for an extended period. Common examples of safety hazard workplaces are those that could expose workers to radiation, UV rays of the sun, and loud noise.

- Workload Hazard – It refers to the excessive stress or strain that a worker experiences while performing their job. For example, it could refer to working in a warehouse or factory wherein you have to stand on hard surfaces for several hours a day (if not your entire shift).

- Biological Hazard – This type of workplace is the most dangerous of all since workers are exposed to dangerous substances and harmful chemicals, including infectious materials. Examples of workplaces with biological hazards are hospitals and laboratories.

- Ergonomic hazard – This type of workplace is for workers who put a strain on their body due to the nature of their work. It can include lifting heavy items or standing for long periods of time. It could result in poor posture or injuries without adequate support for the workers.

It is essential to assess the type of hazard or risk present on each job site. Identifying the risks will help match the footwear solution according to the conditions which the workers are exposed to. Whether you’re dealing with extreme temperatures or at risk of falling heavy objects, there are appropriate safety shoes to provide the protection you need. Conduct a job hazard analysis so you can identify the best foot protection.

Material advancements play a significant role in shifting the safety footwear industry. It makes it possible for workers to find the best material that can offer protection and comfort year-round.

2. Improved Safety with Innovative Features

As technology evolves, there are new features and innovations that have been introduced into footwear design, helping improve the safety and well-being of employees, which also impacts their productivity. And the less injuries or illness that workers experience, the more productive the job site can get.

One example of new features on safety workwear is temperature regulation. Keeping the feet comfortable under extreme temperatures is among the biggest challenges on the job site. It is common in food storage and construction sites. For example, workers can work under extreme heat and then in rainy conditions on other days. When it comes to warehousing and food storage, these workers are also exposed to fluctuating weather conditions. Designing the right safety shoes built for both types of extreme weather can be challenging. Therefore, manufacturing shoes with temperature regulation capabilities is the best solution to eliminate the need to buy a different pair of shoes to adapt to the changing conditions.

Aside from temperature regulation, choosing advanced materials is also critical in improving the foot protection of workers. You can now find a larger selection of breathable materials, enhancing comfort for workers dealing with warmer climates. Cooling textiles are popular in designing safety shoes for workers in warmer areas. These materials utilize conductive fibers that enable them to dissipate heat quickly and keep the feet cool. Meanwhile, they come with a lining that ensures adequate protection against work hazards.

Next on the list of innovative features for safety shoes include the lace-up systems. Nowadays, quick-lacing shoes are the norm. Instead of the traditional lace closure, many new industrial shoes feature a dial to ensure a secure fit. From the safety perspective, a quick-lacing system provides excellent fit and protection.

3. Precision Fit

As mentioned above, a secure fit is critical for foot safety, especially in hazardous work environments.

Fit is the foundation of security, durability and stability for the footwear. When fit is compromised, so is the rest of your foot safety.

Nowadays, many industrial shoe brands offer customization options to allow customers to get the best fit and reduce the chances of foot injury at work. New fitting technologies, such as 3D mapping and AI, provide a more accurate measurement for a more customized fit. These technologies analyze the arch, width, size, and shape of the foot, ,with some even considering the various pressure points for each foot. This last part is crucial in designing safety shoes that meet the various needs for a specific work environment.

4. Material Quality

Innovative materials play a crucial role in the evolution of the footwear industry. As mentioned, cooling textiles and other materials that enhance breathability are growing in popularity, even among industrial shoes. But this technological development does not stop there.

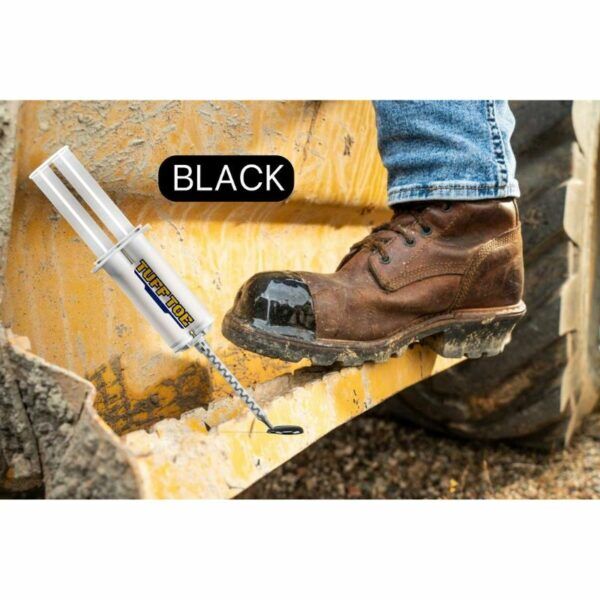

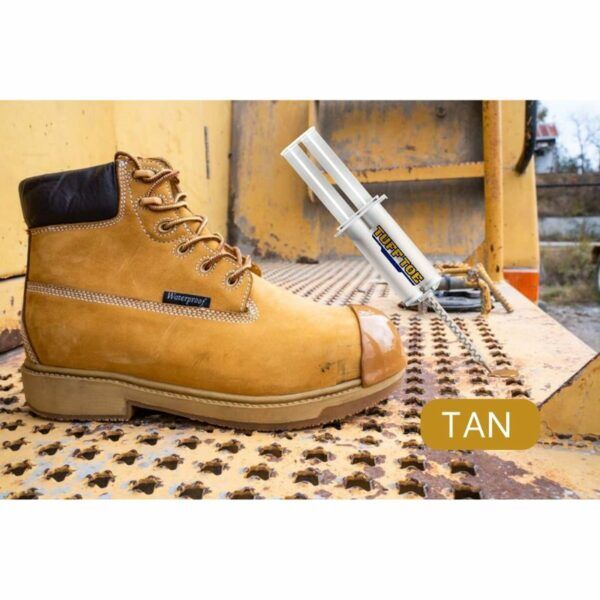

One example of advancement in material quality in industrial shoes is the use of non-metallic safety toe caps. A big criticism of earlier safety shoe models was that they were too bulky and heavy that it made wearing them uncomfortable. New technological developments and research have produced newer materials that offer the same protection as traditional steel toe caps without the added weight and bulk.

As the quest to find the best protective shoes for workers continues, expect new technologies and designs to make it into the market. It is good news for workers as it gives added protection against various kinds of work hazards.